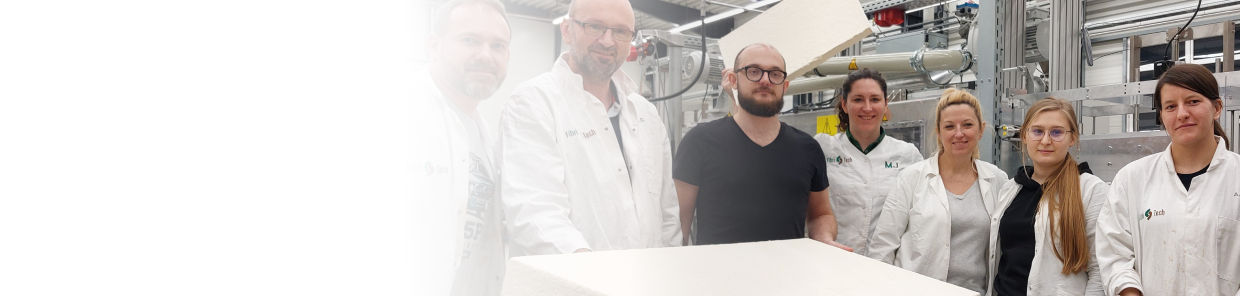

Fibri Technology

Fibrex material base structure

is spatially mouldable in 3D.

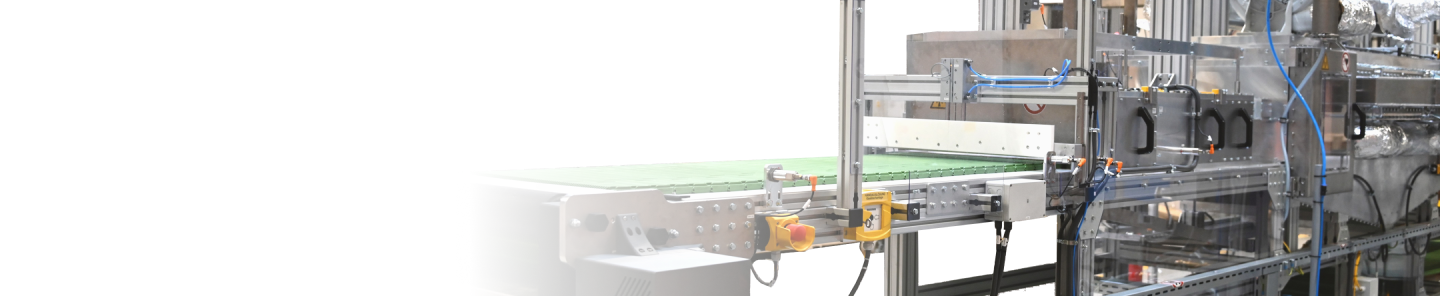

We provide solutions involving the supply of: eco-materials, manufacturing technology, complete production lines with implemented technology, production plants at the customer’s location or in the GreenField model.

We offer 3D spatial materials: of defined (virtually any) shape, in the form of sheets of defined thickness or blocks.

Our material can be characterized by uniform density and structure, or it can be a material with variable parameters in cross-section and volume.

Our technology allows us to make materials:

3D porous fibrous advanced eco material

100% renewable resources

Recyclable and biodegradable

Technical parameters:

Structural properties:

- Density: 40 – 200 kg/m³.

- Can be molded into virtually any three-dimensional shape.

- Available in blocks of specified thickness.

- Tunable density: uniform or varied through the thickness.

- Controlled fibre orientation/anisotropy.

Mechanical properties:

- Compressive strength: 50 to 1000 kPa at 10% strain.

- Young’s modulus: 2 – 20 MPa.

- Contributing to amplitude damping and phase shifting.

Hydrofobicity:

- Can be programed as needed.

- Can float on water few mounts, or soack water beter than songe.

Thermal properties:

- Thermal conductivity (λ): 0.041 W/(m·K) as measured with ISO 8302:1999.

0.036 W/(m·K) currently under development. - Specific heat capacity: 2100 J/(kg·K),

- Water vapour permeability: High, owing to open-pore structure.

Sound absorption:

- Coefficient (αw): 0.95 for thickness>60.

- Sound absorption class: A

Fire performance:

- Reaction to fire classification (EN 13501-1): B-s1, d0 (in development).

Sustainability:

- Fully recyclable and biodegradable.

Contact Us

Biomaterial technology

breakthrough